Rebuilding Transfer Robot for LCD Line

Duration

June 2006 - April 2007 and August 2008 - May 2009

Background

On the Liquid Crystal manufacturing line we used for LCD products such as mobile phones or digital cameras, the 4-Axis Vertical Multi-Articulated Parallel Link Arm Robot (manufactured by a European company "B") that was used for glass transfer had been working for 7 years but it started to suffer a few short time breakdowns.

There were several causes, but the most notable was servomotor's shaft being broken. This servomotor was manufactured by a French company "A" and used DC100W power output. When we received this robot from the company "B", this robot was already discontinued and had to be replaced if it broke.

By replacing this servomotor with a Japanese counterpart, we could prolong the lifetime of the robot without much cost and could also speed up the transfer.

I did this in a company named "C".

Overview

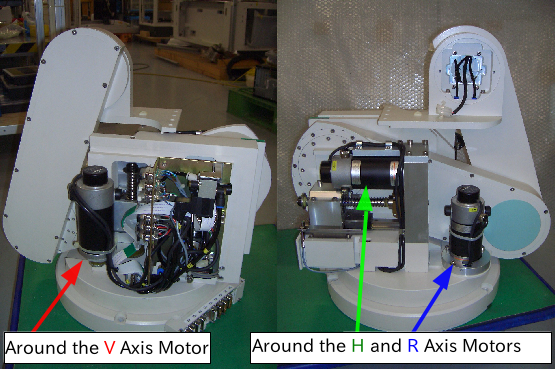

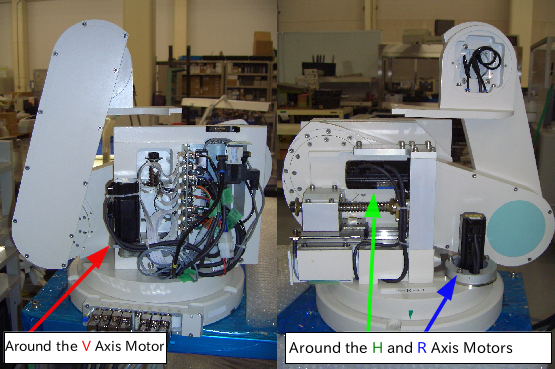

The robot before the rebuild is shown in Photo 1, and the robot after the rebuild is shown in Photo 2.

| V | Vertical |

|---|---|

| H | Horizontal |

| R | Rotation |

| L | Linear |

|

|

|

| Before | After | |

|---|---|---|

| Servomotor | DC100W (Manufactured by a French company "A") |

AC100W (Manufactured by a Japanese company "D") |

| Driver | Company B's Proprietary | Company D's |

| Controller | Company B's Proprietary | PC |

| OS | Company B's Proprietary | Microsoft Windows |

| Application | Pascal | Our own |

| Robot's Max Velocity | Normal | Became Twice after Rebuilding |

| Repeatability | ±0.5mm | ±0.5mm |

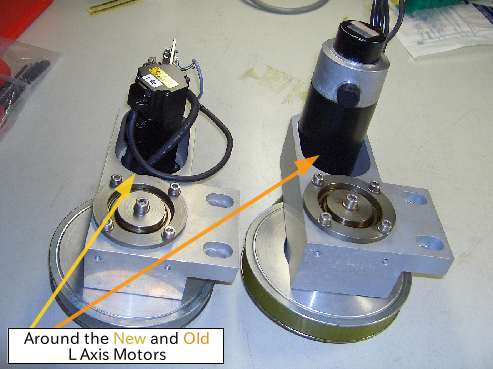

| Old | New |

|---|---|

|

|

After the rebuild, the servomotor's size looks only the half of the original. However, it generates more torque for better speed. By changing the power from DC to AC there were some problems caused by noise; we fixed this problem by adding a shielded electrical wire to the multilayered spiral tape wire.

|

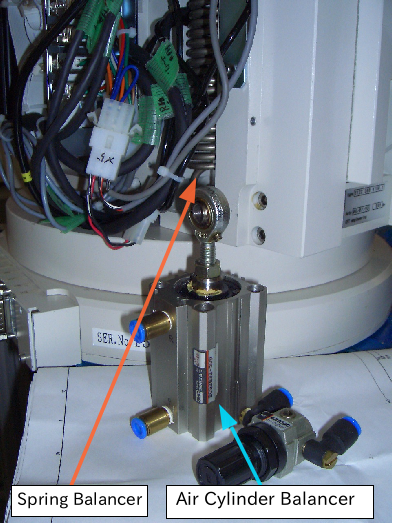

On year 200X, the cylinder balancer has leaked air. I guess it was caused by a misalignment. On the next year, we changed the balancer from a cylinder to a tension coil spring, and by doing so, the cylinder regulator and tubes were no longer required.

|

|

The rebuild cost was no larger than 900,000JPY per robot (Spring Balancer Type) so it was cost effective! After the rebuild the robots keep working for another decade, provided you take care of them.