Retrofit of transport robot for Liquid Crystal line

Background

We made a plan to construct a new Liquid Crystal manufacturing plant so we can increase the production of LCD products such as mobile phones or digital cameras. In order to save budget, we have retrofitted dozens of imported robots as glass transfer apparatuses in TFT production line. Although they are prototypes using 4-Axis Vertical Multi-Articulated Parallel Link Arm, as of 2018, they are working well over 17 years (aside of a few short time breakdowns).

I did this in a company named "C".

Overview

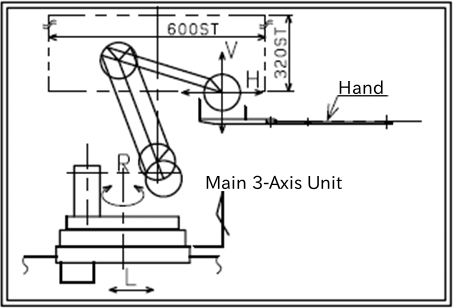

Figure 1 shows the outline of a 4-Axis Vertical Multi-Articulated Parallel Link Arm Robot.

|

At first glance it may look like 5-axis, but the parallel link is built inside the arm, V and H drive units are placed only at the root of the arm, and the arm fulcrum doesn't require any drivers such as servo motors. An integer multiple (x7 for V axis and x6 for H axis) of a slight stroke of the root of the arm is extended to the stroke of the hand. H and V axis can operate independently and doesn't require interpolation from a software.

If the arm is pulled back to the main body, the arm fits inside a small space. If the arm is protruded to its fullest extent, it can secure a stroke of 600mm. The hand is designed to be always horizontal in the operating area.

Specification

| Type | 4-Axis Vertical Multi-Articulated Parallel Link Arm Robot | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Repeatability | ±0.5mm | ||||||||||||||||||||

| Stroke |

|

||||||||||||||||||||

| Max Velocity |

|

||||||||||||||||||||

| Payload | 2kg (Hand) | ||||||||||||||||||||

| Body Weight (3-Axis) | 45kg | ||||||||||||||||||||

| Total Body Weight (4-Axis) | Around 600kg | ||||||||||||||||||||

| Control Type | PTP | ||||||||||||||||||||

| Power Supply | 220V,60Hz | ||||||||||||||||||||

| CDA | 5kg/cm2 | ||||||||||||||||||||

| Vacuum | Factory's Utility | ||||||||||||||||||||

| Exhaust | Factory's Utility | ||||||||||||||||||||

| OS | Company B's Proprietary | ||||||||||||||||||||

| Control Boards | Company B's Proprietary | ||||||||||||||||||||

| Driver Boards | Company B's Proprietary |

|

Actions

- Disassembly and Inspection

Wire harness handling, Obtaining mechanism and maintenance parts, and Consideration of OS and applications usability - Durability Test

We did a 400-hours nonstop durability test for checking the reliability of mechanisms and controls, and we found out that it is usable. - Remove Unneeded Parts

Removed all parts except for the parts needed for automation: 3-Axis robot body, liner axis, and various structures that are not frames. - Deciding the layout between other manufacturing apparatuses

We analysed the parallel link mechanism to make the operating range clear. We placed this robot to 17 second-handed WET apparatuses which covers the half of TFT line. (34 robots were second-handed) - Designing and Applying the Safety Cover and Utility Connector. We also had set up display devices and keyboard.

- What to do on troubles

We had set up a procedure to replace the main 3-Axis unit in short time. We also decided to reserve 19 robots for backup. - Inter-device Intersection Test

We conducted a test between other manufacturing apparatuses regarding the transfer of products and communication of signals. - Line Placement

We did robot placements (we made a Body Slide Jig to make this task easier), and did teachings. - Coaching of Teaching and Maintenance, and we outsourced the writing of manuals.

Manufacturing Cost

Each robot costed around 490,000JPY. It was only 1/6th cost of a newly designed robot (around 1.6 billion JPY).

(Won Award for TPM Excellence, Category 1 from Japan Institute of Plant Maintenance)