Designing an unloader for a Receive Wash Apparatus

Duration:September 2000 - October 2000

Category:Rebuild

Company:"C"

Background

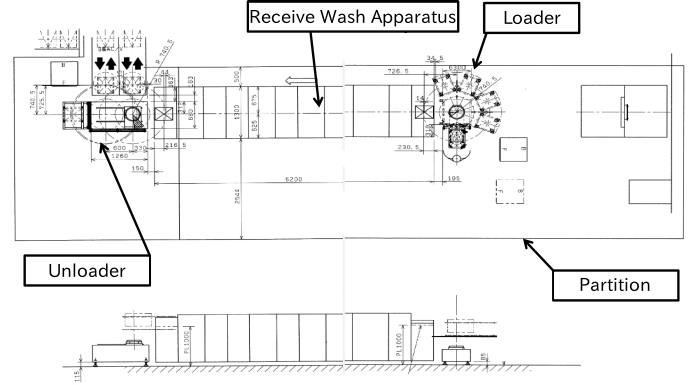

When we set up a TFT line on "C" company's new factory, we did not have enough budget so we had to buy secondhanded apparatuses from a company "M". Of these apparatuses, we added a Board Transfer Robot to the TFT line after several modifications. We were running out of money, so we decided to also use the robot as an "Unloader" at the beginning of the TFT line. In the company named "F", the said robot was used for a totally different perpose, but we modified it and used as an unloader.

Design Details

- Unpacking the apparatus that was used for a different purpose (it came from the company "M")

- Remove portions unneeded for our purpose (Covers, and a Docking Port for Unmanned Automatic Vehicles)

- Recoding the size of the apparatus

- Plotting the remaining parts that will be used in the future

-

Regarding the part 4

- Safety cover design (Protective measures to prevent robots from harming people)

- Design of shelves to put monitors, keyboards etc...

- Design of utility part such as air, vacuum, exhaust etc.

|

|

Installation

- Requested transport from empty process used for rebuild

- Installation was done by ourselves. Due to heavy weight of 600 kg body weight, the slide jig was designed and manufactured beforehand. After installation using this, the earthquake-resistant support stay of the robot body is fixed to the grating.

- Wiring, energization, operation check

- Robot teaching

- Education including teaching to manufacturing personnel

Manufacturing Cost

The robot used here was one of 30 units in the remodeling introduction, and it costed us only about 500,000 yen. This is a price including utilities supply apparatuses such as air, vacuum, exhaust etc, and shelves and safety covers for keyboards, monitors, etc. I built a number of them so the cost was minimum.